2024 Technical Program Sessions

Materials Development

Session Leaders

Birat KC, Quentin Boll, Bin Sun

Material innovations are expanding the application spaces for TPOs, PP and PP Compounds increasing part functionality, styling, cost reductions and light weighting.

Learn more about these new developments:

- Next Generation Glass Fiber and Talc Filler Developments

- Innovative Additives for EV Applications

- Enhancing and Improving Key Properties for Sustainable Materials

And much more!

Sustainability

Session Leaders

Petya Yaneva, Mark Allen, Reddy Murali

In today’s Automotive Industry, lofty OEM sustainability targets, government regulations and a shift in buyer preference are changing how Thermoplastic Olefins will be used in future vehicles.

Learn more regarding:

- Insights from Authorities in Industry and Academia

- Strategic Objectives and Outlook for Sustainability Across the Value Chain

- Polyolefins with Enhanced Sustainability Benefits

- Use of Mechanically Recycled Resin

- Progress on Advanced/Chemical Recycling & Bio Feedstocks

- Strategies for Waste Minimization and Elimination

- Certification and Tracking of Sustainable Content

- Part Design with Circular Content and Reduced Carbon Footprint

And much more!

Innovations In Interiors

Session Leaders

Pravin Sitaram, Hoa Pham, Austin Wagenhals

Evolving Customer Expectations for a premium, seamlessly integrated, and smart Interior pose a formidable challenge for the Automotive Industry to deliver.

Learn more about these Interior topics:

- Emerging Automotive Interior Trends

- Sustainable Materials in Automotive Interior Applications

- Review opportunities with recycled TPE, PP and Polyolefin Foams

- Explore innovative new technologies to create Sustainable A Surfaces.

- Learn how we can reduce carbon footprint in Interior Automotive Materials

- First Surface Material Topics

- Smart Surfaces in automotive trim

- Improving Scratch and Mar to increase customer satisfaction

- CB-FIM processing challenges in visible applications.

Exterior Trim and Structural Applications

Session Leaders

Mark Pilette, Charlie Yang, Kevin DeGrood

Over the last decade the automotive industry has endured major changes especially unprecedented disruption from EVs. This accelerated innovative materials development for the exterior components to achieve desired aesthetics and new functions as well as reduced cost and part weight.

Learn more regarding:

- Translucent TPO Compounds for Innovative Lighting Systems

- Expanded Polypropylene and Foam Bead Molding

- High Strength, High Stiffness TPOs for body panel lightweighting

- Advancements in Glass Filled PP for structural applications

- Automotive innovation and Molding Applications using Expanded Polypropylene Foam

- Design Trends Impacting the car of the future

And much more!

Polyolefin Elastomers and Vulcanizates

Session Leaders

Bhavesh Shah, David Patel, Nadeem Bokhari

TPEs and TPVs are becoming a material of choice in automotive applications to replace thermoset rubbers bringing weight saving, sustainability, cost, sealing performance, and processability advantages. Their application ranges from automotive interior, exterior, and under the hood applications.

Learn about:

- Corner Molding with TPV

- Sustainable TPEs and TPVs

- Product Design with TPEs and TPVs

- Automotive Weather Sealing

- EV Cooling Hoses for Thermal Management

And more!

Performance Additives and Colorants

Session Leaders

Heejung Kwon, John Mara, Raziyeh Mohammadi

Performance Additives and Additive Masterbatches are essential components for enabling the performance of polyolefins to meet the new technology needs for Future Mobility.

Learn about new developments in additives facilitating future trends, such as:

- Ride Sharing:

– Stabilization of Automotive TPO Compounds (Past & Present)

– VOC Emissions – Assessment of VOC emissions from Automotive Materials

– Aesthetics – Developing Polyolefin Compounds with Metallic Look

– Nucleation – Superior PP via use of Novel Nucleating Agents for PP - Electrification:

– Non-Halogenated Flame Retardants offering low smoke characteristics - Sustainability:

– Stabilizers to enhance the processing & LTTS of recycled PP compounds

– Ionic additives to improve Melt Strength in recycled & virgin PP compounds

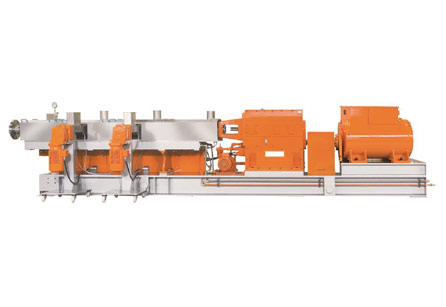

Process Enabling and Additive Technologies

Session Leaders

David Kosse, Anand Bora, Suresh Shah

Manufacturing in today’s challenging and competitive climate requires high levels of efficiency, operational excellence, and the use of advanced technologies. See how some of today’s industry leaders in the Polyolefin Compound Industry are blazing new trails to rise to these challenges.

Learn about:

- Advanced Simulation Methods Understanding Scratch

- A Critical Cost Evaluation of Polymer Coloring Methods

- Injection Molded TPO Foam

- Innovations in Additive Manufacturing (3D Printing)

- Use of AI for Compounding with Bio-Based Materials

And much more!